Tipi komuni ta 'cutters tat-tħin

Tipi komuni ta 'cutters tat-tħin

1) Cutters tat-tħin tad-diska ġeneralment huma magħmula minn xfafar jew kapijiet tal-cutter imwaħħlin fuq korp tal-cutter b'forma ta 'diska, u ħafna drabi jintużaw għat-tħin tat-tmiem ta 'ajruplani akbar.

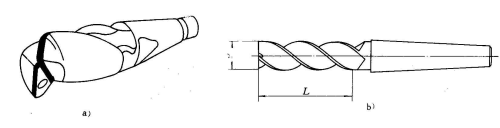

2) End mills End mills are the most commonly used milling cutters in CNC milling, u jintużaw ħafna biex jipproċessaw partijiet ċari. Figure 4-3 shows the two most common end mills. In addition to milling with its end edge, the end mill is also commonly used for milling its side edge. Sometimes the end edge and the side edge are milled at the same time. The end mill can also be called a cylindrical milling cutter.

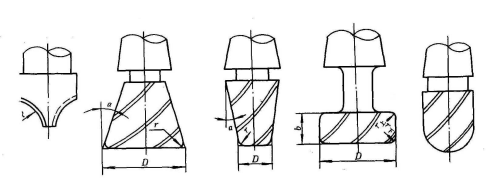

3) Forming milling cutters Forming milling cutters are generally specially designed and manufactured for specific workpieces or processing contents. They are suitable for processing specific shapes of planar parts (such as angled surfaces, grooved surfaces, eċċ.), and are also suitable for special-shaped holes or tower. Figure 4-4 shows several commonly used form milling cutters.

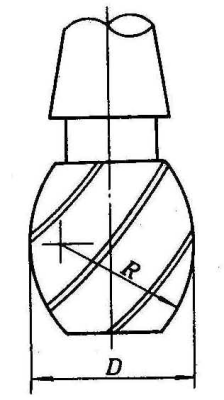

4) Ball end milling cutter. It is suitable for processing space curved surface parts, and sometimes it is also used for supplementary processing of larger transfer concave arcs of planar parts. Figure 4-5 is a common ball end milling cutter.

5) Drum milling cutter. Figure 4-6 is a typical drum-shaped milling cutter, which is mainly used for approximate machining of variable bevel surfaces of variable bevel parts.

In addition to the above-mentioned types of milling cutters, CNC milling machines can also use various general-purpose milling cutters. Madankollu, because many CNC milling machines have special broaching devices in the spindle, or because the taper of the spindle inner hole is different, transition sleeves and tie rods must be prepared.