밀링 커터와 드릴의 차이점은 무엇입니까?

밀링 커터와 드릴의 차이점은 무엇입니까?

밀링 커터: 밀링 커터는 하나 이상의 톱니가 있는 회전 도구입니다.. 일할 때, 각 칼날은 간헐적으로 공작물의 여유분을 차례로 잘라냅니다.. 밀링 커터는 주로 평면 가공에 사용됩니다., 단계, 그루브, forming surfaces and cutting off workpieces on milling machines. To ensure that a sufficiently high average chip thickness/feed per tooth is used, the correct number of milling cutter teeth for the operation must be determined.

일반적으로, milling cutters are divided into:

1. Flat-end milling cutter for rough milling, removing many blanks, and fine milling of small horizontal planes or contours.

2. Ball end milling cutter, for semi-finishing and finishing milling of curved surfaces; small ball end milling cutter can finish milling of small chamfers on steep surfaces/straight walls and irregular contour surfaces.

3. The flat-end milling cutter has a chamfer, which can be used for rough milling to remove many blanks and finely milled with small chamfers on flat surfaces (relative to steep surfaces).

4. Forming milling cutters, including chamfering, T-shaped milling or drum-shaped, tooth-shaped, and inner R cutters.

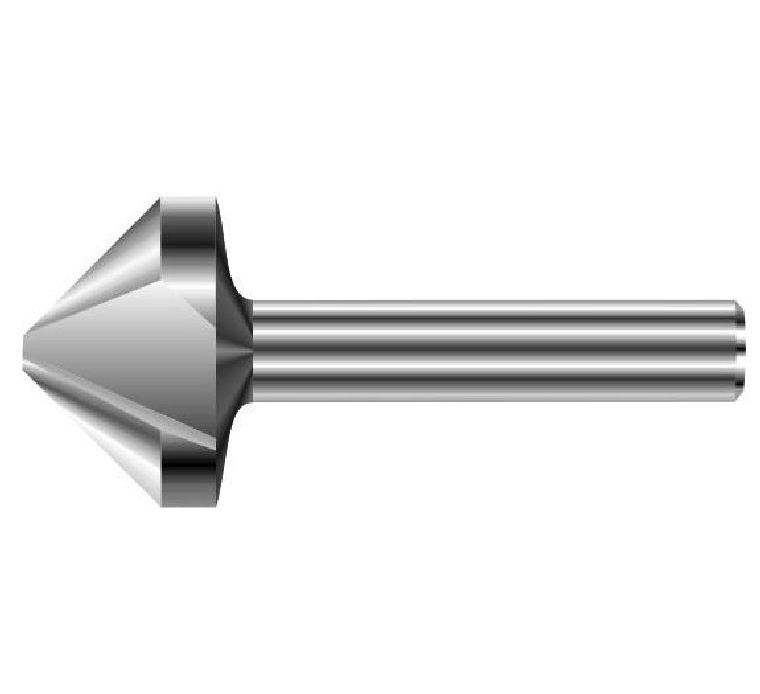

5. Chamfering cutter, the shape of the chamfering cutter is the same as that of chamfering, divided into milling cutters with rounded chamfers and bevelled chamfers.

6. T-shaped knife can mill T-shaped slots.

7. Tooth cutter, milling out various tooth shapes, such as gears.

8. Rough leather knife, a rough milling cutter designed for aluminum-copper alloy cutting, can be processed quickly