Internal calibration procedures for outside micrometers

Internal calibration procedures for outside micrometers

The width of the vertical engraved line on the fixed sleeve and the engraved line on the differential cylinder is (0.08~0.20)mm, and the difference in engraved line width should not be greater than 0.03mm.

- The distance from the end edge of the conical surface of the differential cylinder to the engraved surface of the fixed sleeve

The distance between the end edge of the conical surface of the differential cylinder and the engraved surface of the fixed sleeve should not be greater than 0.4mm. - The relative position of the end face of the conical surface of the differential cylinder and the millimeter mark on the fixed sleeve

When the zero scale line of the micron tube is aligned with the vertical scale line of the fixed sleeve, the end face of the conical surface of the micron tube should be tangent to the right edge of the millimeter scale line of the fixed sleeve. If there is no tangency, the allowable line pressure should not be greater than 0.05mm, and the off-line should not be greater than 0.1mm. - Surface roughness of working surface

The surface roughness of the working surface of the outer diameter micrometer and calibration rod should not be greater than Ra0.05μm. - Flatness of working surface

The flatness of the working surface should not be greater than 0.6μm. - Parallelism of two working surfaces

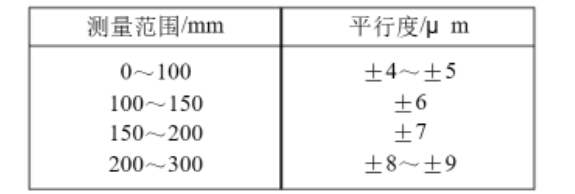

The parallelism of the two working surfaces should be within the range specified in Table 2.

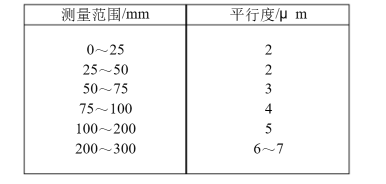

6、 The indication error of the outer diameter micrometer should be within the range specified in Table 3