Technical requirements for cemented carbide indexable inserts

Technical requirements for cemented carbide indexable inserts

1 Technical requirements for indexable inserts with round holes, non-hole and counterbore cemented carbide

(1) The straightness of the back of the blade is not more than 0.05mm concave inward and not more than 0.03mm convex outward.

⑵, the flatness of the base surface of the blade, the blade with a round hole and the non-hole blade are only allowed to be concave inward, and the value is not greater than 0.05mm; the counterbore blade is only allowed to be concave inward, and the value is not greater than 0.03mm.

⑶. The surface of the blade must not have defects that are harmful to use, and the cutting edge must not have any edge or corner; the edge or corner of the non-working part should not be greater than 0.3mm.

⑷. The main performance and organizational structure of the blade should comply with the provisions of YB849-75 “Carbide Grade” or related standards.

⑸. The section structure of the blade should be uniform, and there should be no defects that are harmful to use.

⑹. All newly developed or introduced new materials should be higher than the YB849-75 standard and meet the recommended value of the enterprise.

2 Technical requirements for cemented carbide indexable milling inserts

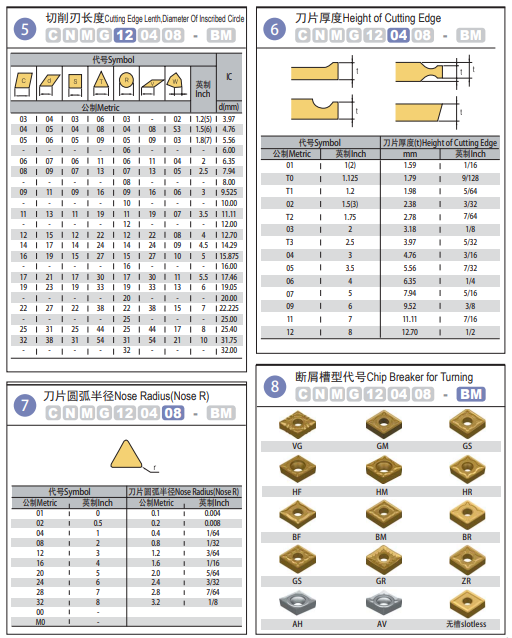

(1) The surface roughness of indexable milling inserts should meet the requirements of the following table:

Allowable deviation level Front and rear (Ra) Wiper rear (Ra)

A 0.4 0.4

C 0.8 0.8

K 1.6 0.8

E 1.6 0.8

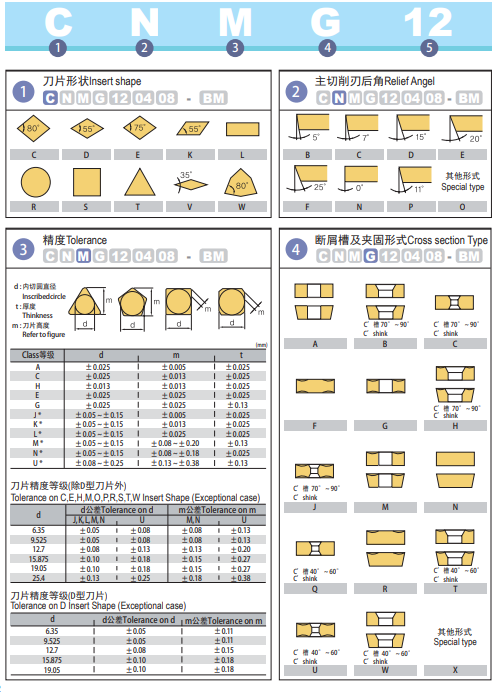

(2) The tolerances of d, m and s of milling inserts commonly used in precision grades A, C, E, and K are shown in the table below.

d Allowable deviation of d Allowable deviation of m Allowable deviation of s

Deviation class Deviation class Deviation class

A, C, E K A C, K E A, C, E, K

6.35 ±0.025 ±0.05 ±0.005 ±0.013 ±0.025 ±0.025

9.525 ±0.05

12.70±0.08

15.875 ±0.10

19.05±0.10

⑶. The straightness of the base surface of the blade is only allowed to be concave inward, and the grade A is not greater than 0.005mm; the grade C is not greater than 0.01mm; the grade K and E is not greater than 0.02mm.

⑷. The surface of the blade must not have defects that are harmful to use, and the cutting edge must not have any edge or corner; the edge or corner of the non-working part should not be greater than 0.3mm.

⑸. The main performance and organizational structure of the blade should comply with the provisions of YB849-75 “Carbide Grade” or related standards.

⑹. The section structure of the blade should be uniform, and there should be no defects harmful to use.

3. Other common technical essentials of cemented carbide indexable inserts

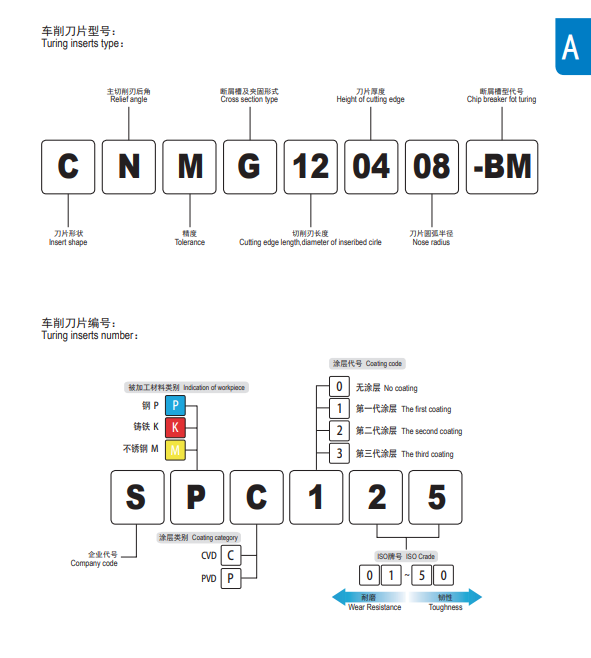

⑴ For blades with surface chemical coating (CVD), including turning blades, milling blades or other carbide blades, the cutting edge of the blade must be rounded before coating, and the radius of the cutting edge γε≤5μm.

⑵. For indexable inserts that do not mark the clearance angle tolerance, the allowable deviation is ±1°; in addition, the radius of the tool nose arc γε≤1.0mm, the allowable deviation is ±0.1mm, γεr>; 1.0~2.0mm, The allowable deviation is ±0.15mm.

For indexable blade products, each blade should be engraved or etched with identifiable marks, such as: material category or coating code, etc.