Basic knowledge of thread rolling board and answers to frequently encountered problems

Basic knowledge of thread rolling board and answers to frequently encountered problems

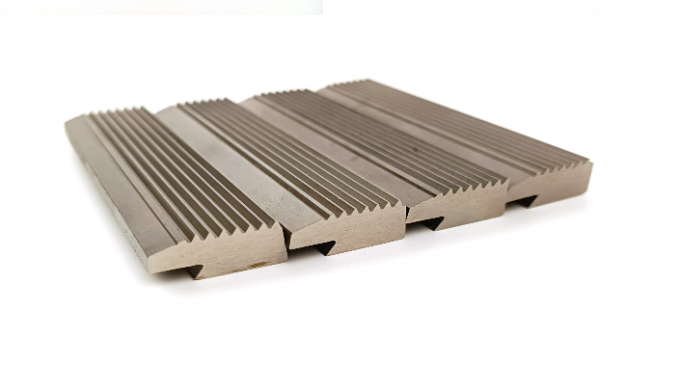

- Feeding area: that is, during the adjustment process, the bare nails are fed to the compacted part. In order to facilitate feeding, anti-skid teeth are often engraved on the feeding area and the shaping area;

- Shaping area: after the light nails pass through the feeding area, the light nails squeeze the shaping part;

- Forming area: After the light nail passes through the feeding area and the shaping area, the light nail is extruded into a screw according to the angle of the tooth groove, tooth front, and tail of the tooth plate;

- Discharge area: the part of the discharge after the screw is formed;

- Dorsal angle and elevation angle: It is the part where the material is cut in the sharp tail die plate and the sharp mouth is formed. The size of the dorsal angle is the key to controlling how much material is fed into the cusp. A large dorsal angle feeds more material, while a small dorsal angle feeds less; the elevation angle is the key to the formation of the cusp and the tooth front on the cusp. The tail, the tail is not cut cleanly; if the elevation angle is raised, the tip will be broken, and the light nail will be cut off prematurely;

- Incision: the part where the dorsal angle intersects with the tip and tail of the tooth plate, the incision is required to be very sharp, if the incision is too blunt, the material will be cut continuously, resulting in tailing and inconsistent shape of the tail tip;

- Tooth depth: that is, the depth of the screw tooth front, and the tooth depth is the key to controlling the outer diameter of the screw;

- Yashan angle: the angle of the screw tooth front. There are special regulations on the angle of Asan for special screws, and Asan for C/B fiberboard screws

40 degrees; BA round tail screw general Asan angle 475 degrees; general triangular double wire self-tapping Yashan angle 45 degrees: general

Machine tooth Yashan 58 degrees ~ 60 degrees; Yashan angle is also the key to control the outer diameter of the screw. - Angle of tail tip: the angle of the tail tip of the screw. Generally, the tail tip of ordinary self-tapping screws is between 40 degrees and 50 degrees; special screws have special regulations, for example: wallboard screws and fiberboard screws generally have tail tips at 20 degrees Between degrees and 30 degrees; machine microphone

The screw is generally between 80 degrees and 90 degrees; sometimes the customer will specify the angle of the tail tip; - Chamfering: That is to say, during the production process of the tooth plate, the feeding area and the shaping area are milled very sharply and sharply, the purpose is to facilitate feeding. If the plastic chamfer is too sharp, the tooth plate will not be wear-resistant; if the chamfer is too blunt, the plane of the feeding area at the tail is too large, the screw forming is difficult, and the outer diameter will not be large enough; the feeding area of the chamfering is too worn, easy to As a result, the screw is not formed enough, the screw diameter is not large enough, and it slips.

- Anti-slip teeth: That is to say, the light nails are specially engraved on the feeding area and forming area of the tooth plate in order to prevent slipping during the feeding and forming process. If the anti-slip teeth are shallow, it will cause slipping, and if the anti-slip teeth are deep, it will easily cause screws. The bottom diameter is not smooth, the tooth front is not bright, and even the extrusion of the smooth nail is blocked, resulting in a small screw outer diameter;

- Spike tail height: that is, the distance between the tooth surface of the die plate and the cutting edge, which is generally half of the bottom diameter of the screw. If the tail height is too high, the screw cuts will collide and the screw is not formed enough; if the tail height is too low, the tail will Cut off the material and drag the tail.