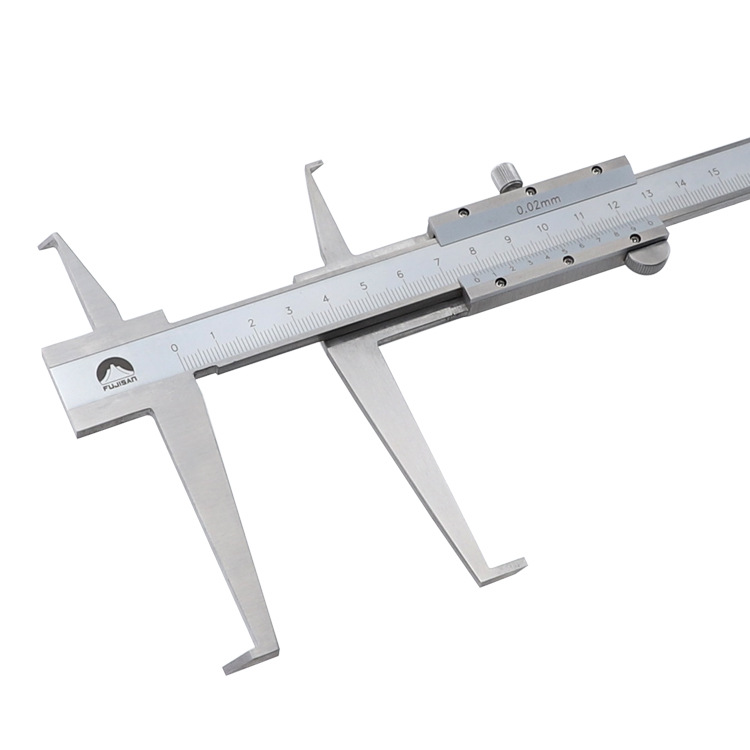

Inner diameter dial indicator

Inner diameter dial indicator The surface roughness of the expansion spring-type inner diameter gauge does not exceed 0.1um. The measuring steel of the steel ball-type inner diameter gaugeThe surface roughness of the ball and positioning steel ball shall not exceed 0.05um. Radius sample for probe spherical radiusBoard comparison. The requirements are all less than 1/2…