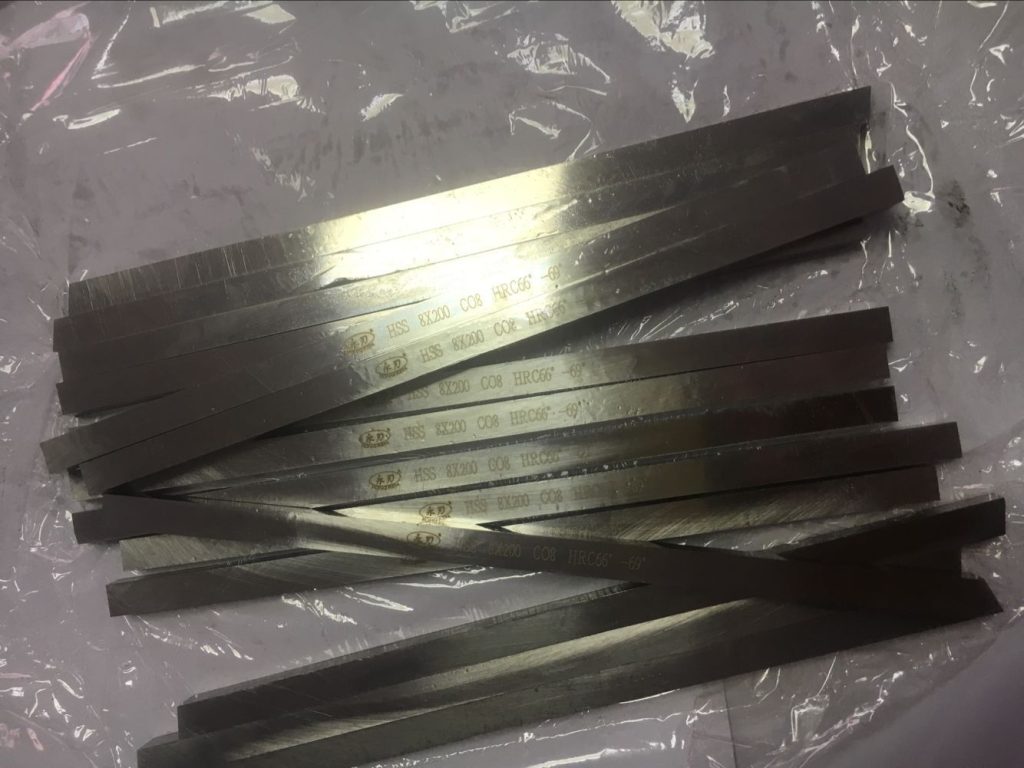

High Speed Steel Square Turning Tool

High Speed Steel Square Turning Tool

The square turning tool bar is made of high-speed steel tool steel, which has good toughness and high strength. It is mainly used for processing the outer circle, end face, inner hole, thread and other processes of general lathes, semi-automatic and automatic lathes.

Coating of white steel knives

The coating has the characteristics of high surface hardness, good wear resistance, stable chemical properties, heat resistance and oxidation resistance, small friction coefficient and low thermal conductivity. When the coating is cut, it can increase the service life by more than 3 to 5 times compared with the uncoated one. The cutting speed is 20%~70%, the machining accuracy is improved by 0.5~1 grade, and the consumption cost is reduced by 20%~50%.

- good economy

It is made of high-speed steel, which has good toughness and high hardness. The cutting geometric parameters can be ground on demand. It is cost-effective and can be used in a considerable amount. - good craftsmanship

For ease of manufacture, the material is required to have good machinability. Including hot workability (thermoplasticity, weldability, hardenability) and machinability. - High hardness and wear resistance

The hardness of the material must be higher than that of the workpiece material. At room temperature, it should generally be above HRC60. Generally speaking, the higher the hardness of the material, the better the wear resistance. - sufficient strength and toughness

The cutting part has to bear a lot of cutting force and impact force. Therefore, the material must have sufficient strength and toughness. - Good heat resistance and thermal conductivity

The heat resistance of a material refers to the ability to maintain its hardness and strength at high temperatures. The better the heat resistance, the stronger the material’s ability to resist plastic deformation and wear at high temperatures. The better the thermal conductivity of the material, the easier it is to conduct the heat generated during cutting, thereby reducing the temperature of the cutting part and reducing wear. Guangzhou imported white steel turning knife imported round turning knife round rod Swedish white steel turning knife strip

When high-speed steel is cut at high speed, the damage form is mainly wear and tear. The cause of damage varies with the material and workpiece material, mainly due to wear, but some are mainly due to damage. Or it is damaged by wear accompanied by micro chipping. With the increase of cutting speed and cutting temperature, the wear mechanism is mainly adhesive wear and chemical wear, so the choice of white steel knives is very important. Although the comprehensive performance of cemented carbide on the market is very good, but the cost is high, it is not suitable Processing and production in large factories, so white steel knives still occupy a dominant position in the market. The cobalt-containing white steel knives imported by Deren factory have high toughness and cutting life. The white steel knives of the same material can increase your processing efficiency by 30%.

سلام خوبین .

چرا فعال نمیشه

Thank you for your reply. How can I help you

Hi

How are you

Why active

Thank you for your reply. How can I help you