How to use universal protractor

How to use universal protractor

- Universal angle ruler is suitable for measuring internal and external angles in machining. It can measure 0°-320° external angles and 40°-130° internal angles.

- The principle and use of the universal angle ruler: The universal angle ruler is a measuring tool used to measure the internal and external angles of the workpiece.

The reading mechanism of the universal angle ruler is based on the vernier principle. Each division on the main scale is 1°. The engraved line of the vernier is divided into 30 divisions by taking 29° of the main scale. Therefore, the angular division of the vernier scale is 29°/30, that is, the difference between the main scale and the vernier scale is , which means that the reading accuracy of the universal angle ruler is is 2/. The reading method is exactly the same as that of a vernier caliper.

When measuring, the zero position should be calibrated first. The zero position of the universal angle ruler is when both the square ruler and the ruler are installed, and the bottom edge of the square ruler and the base ruler are in contact with the ruler without gaps. At this time, the main ruler and the vernier are at “0” line alignment. After adjusting the zero position, any angle within the range of 0-320° can be tested by changing the mutual positions of the base ruler, square ruler and ruler.

- Basic operating steps of universal energy protractor:

- When measuring, first adjust the position of the square or ruler according to the condition of the measured part of the product.

- Then tighten them with the screws on the clamping block, and then adjust the angle between the measuring surface of the base ruler and other relevant measuring surfaces.

At this time, first loosen the nut on the brake head and move the main scale for rough adjustment.

- Then turn the micro-motion device on the back of the sector plate for fine adjustment until the two measuring surfaces are in close contact with the measured surface.

- Then tighten the nut on the brake and take off the angle ruler for reading.

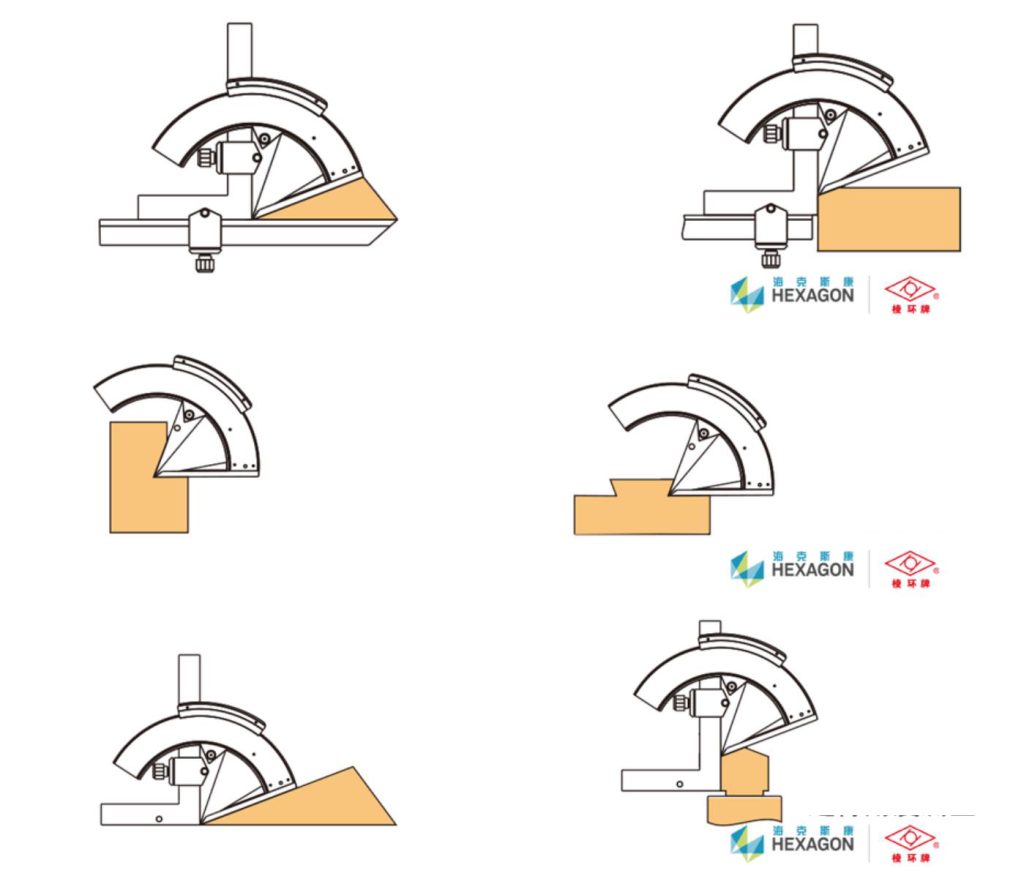

- The following details how to use it in different situations:

- Measure the angle between 0°-50°

The square and ruler are all installed, and the measured part of the product is placed between the measuring surfaces of the base ruler and ruler for measurement.

- Measure the angle between 50°-140°

You can remove the square and install the straightedge to connect it with the sector board. The measured part of the workpiece is placed between the measuring surfaces of the base ruler and the ruler for measurement. You can also just remove the ruler and clamping block without removing the square, and then pull the square downward until the intersection of the short side and the long side of the square is aligned with the sharp edge of the base ruler. Place the measured part of the workpiece between the measuring surfaces of the base ruler and the short side of the square ruler for measurement.

- Measure the angle between 140°-230°

Remove the ruler and clamping block, install only the square, but push the square up until the intersection of the short side and the long side of the square is aligned with the sharp edge of the base square. Place the measured part of the workpiece between the measuring surfaces of the base ruler and the short side of the square ruler for measurement.

- Measure the angle between 230°-320°

Remove all squares, rulers and clamps, leaving only the sector plate and main ruler (with base ruler). Place the measured part of the product between the base ruler and the sector plate measuring surface for measurement.