Complete specifications and models of chamfering cutters and milling cutters

Complete specifications and models of chamfering cutters and milling cutters

Chamfering cutters and chamfering milling cutters are commonly used tools in machining for chamfering and milling workpieces. This article will elaborate on the specifications and models of chamfering cutters and chamfering milling cutters, the rotation speed and feed rate of chamfering cutters of milling machines, and related products of Saichi precision tools.

- Specifications and models of chamfering cutters and chamfering milling cutters

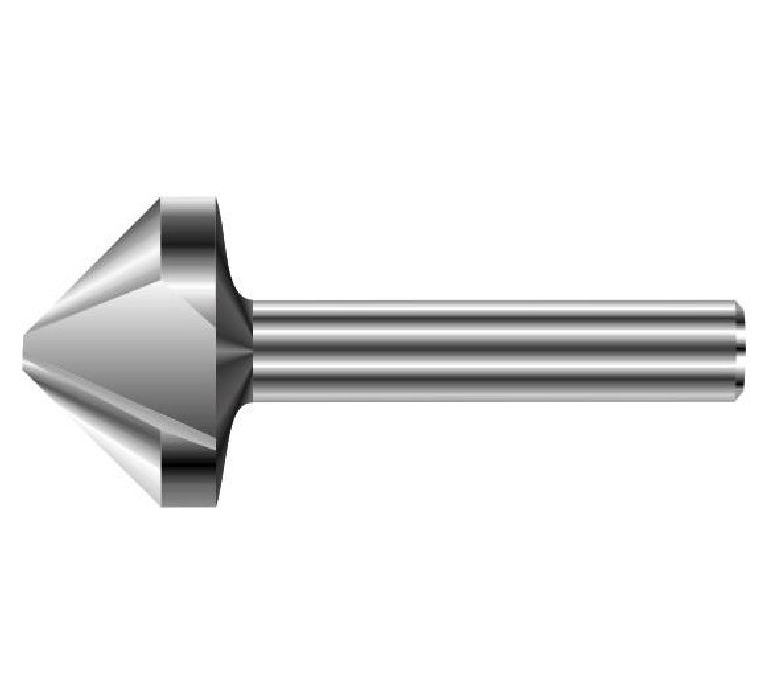

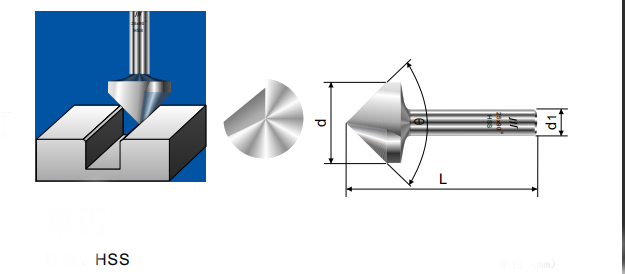

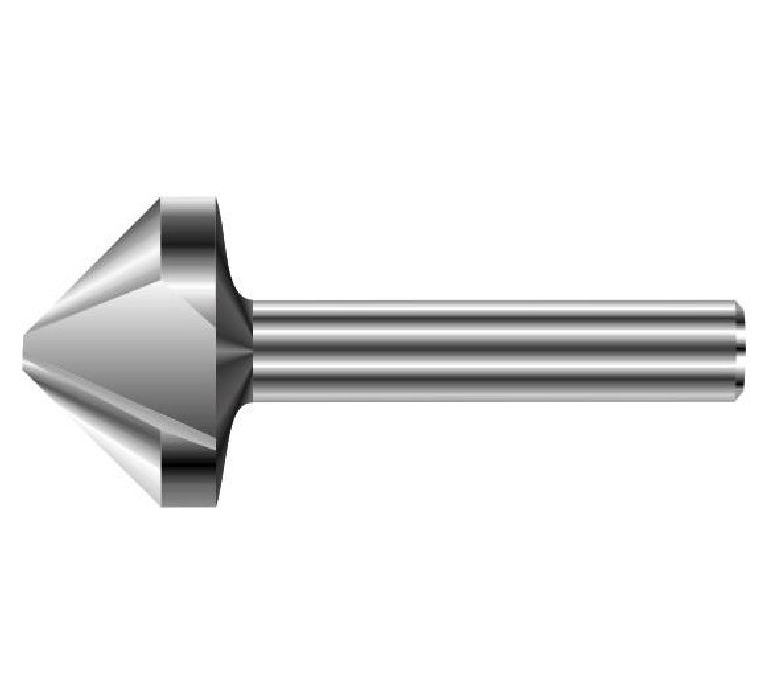

There are various specifications and models of chamfering cutters and chamfering milling cutters. It is very important to choose the appropriate tool according to different processing needs and workpiece materials. Common chamfering cutter specifications include 45 degrees, 60 degrees and 90 degrees, which are suitable for chamfering at different angles. The specifications and models of chamfering milling cutters include diameter, number of blades, blade length and other parameters. Choose the appropriate tool according to the processing requirements.

The selection of specifications and models of chamfering cutters and chamfering milling cutters should consider factors such as workpiece material, processing accuracy, and processing efficiency. For materials with higher hardness, you can choose tools with fewer edges but longer edges to improve cutting efficiency. For workpieces that require higher machining accuracy, you can choose a tool with a larger number of edges to obtain better machined surface quality.

- The rotation speed and feed rate of the chamfering cutter of the milling machine

The rotation speed and feed rate of the chamfering cutter of a milling machine affect the machining effect and tool life. If the rotation speed is too high, it will cause increased tool wear, while if the rotation speed is too low, it will affect the processing efficiency. If the feed rate is too high, the cutting force will increase, while if the feed rate is too small, the quality of the machined surface will be affected.

Choosing the appropriate rotation speed and feed rate should be comprehensively considered based on factors such as tool material, workpiece material and processing requirements. Generally speaking, for materials with higher hardness, lower rotation speed and feed rate should be selected to reduce tool wear. For workpieces with higher machining accuracy requirements, a higher rotation speed and a smaller feed rate should be selected to obtain better machined surface quality.

- Application of Saichi precision tools in the fields of chamfering cutters and chamfering milling cutters

Saichi Precision Tools is a company specializing in the production of chamfering cutters and chamfering milling cutters. Its product quality and performance are highly recognized. Saichi precision cutting tools use advanced production technology and high-quality materials to ensure the wear resistance and cutting performance of the cutting tools.

The chamfering cutters and chamfering milling cutters of Saichi Precision Tools are widely used in aerospace, automobile manufacturing, mold processing and other fields. Its products have the advantages of stable cutting, high processing accuracy, and long service life, and are favored by many customers.

The specifications and models of chamfering cutters and milling cutters should be selected based on the processing needs and workpiece material. The selection of rotation speed and feed rate of the milling machine chamfering cutter should be comprehensively considered based on factors such as tool material and workpiece material processing requirements. The application of Saichi precision tools in the field of chamfering cutters and milling cutters has been widely recognized, and its product quality and performance are excellent.