What is the difference between a milling cutter and a drill?

What is the difference between a milling cutter and a drill?

Milling cutter: A milling cutter is a rotating tool with one or more teeth. When working, each knife tooth cuts off the allowance of the workpiece intermittently in turn. Milling cutters are mainly used for machining planes, steps, grooves, forming surfaces and cutting off workpieces on milling machines. To ensure that a sufficiently high average chip thickness/feed per tooth is used, the correct number of milling cutter teeth for the operation must be determined.

Generally, milling cutters are divided into:

1. Flat-end milling cutter for rough milling, removing many blanks, and fine milling of small horizontal planes or contours.

2. Ball end milling cutter, for semi-finishing and finishing milling of curved surfaces; small ball end milling cutter can finish milling of small chamfers on steep surfaces/straight walls and irregular contour surfaces.

3. The flat-end milling cutter has a chamfer, which can be used for rough milling to remove many blanks and finely milled with small chamfers on flat surfaces (relative to steep surfaces).

4. Forming milling cutters, including chamfering, T-shaped milling or drum-shaped, tooth-shaped, and inner R cutters.

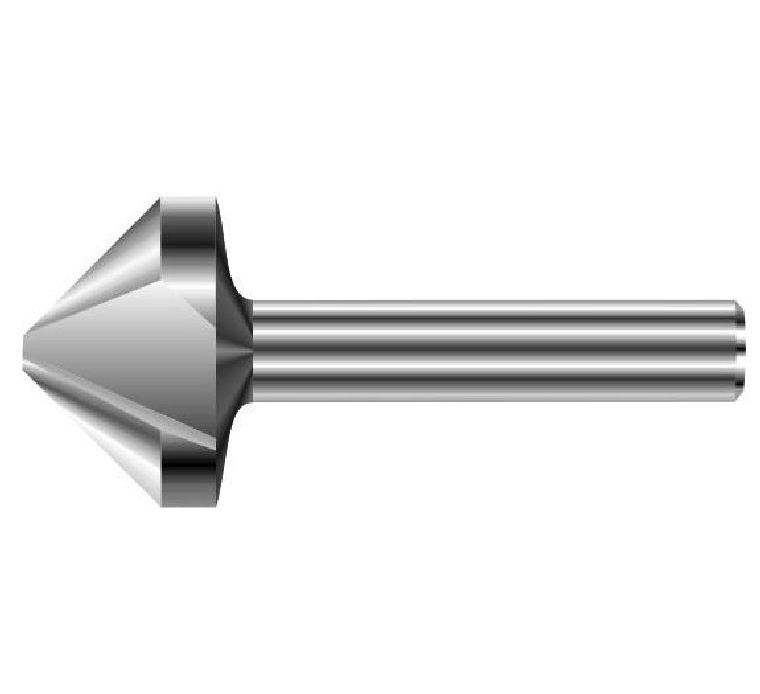

5. Chamfering cutter, the shape of the chamfering cutter is the same as that of chamfering, divided into milling cutters with rounded chamfers and bevelled chamfers.

6. T-shaped knife can mill T-shaped slots.

7. Tooth cutter, milling out various tooth shapes, such as gears.

8. Rough leather knife, a rough milling cutter designed for aluminum-copper alloy cutting, can be processed quickly